Welcome to HydrostreamForums.com

If you're not registered, please consider doing so. It's easy - just click the "Register" link at the top

right corner of the page. Our forum needs members like you to contribute to the site in order to survive.

We are a community of boat lovers and Hydrostream enthusiasts here; we are happy to help anyone

who may need advice or guidance for their 'Stream; and we encourage members to offer their advice

and guidance to others as well. Thank you for visiting our forums, and please register.

We're better than Facebook.

Registering only takes a few minutes and you can do so by CLICKING HERE

If you are a member, don't forget to log in to take full advantage of the forum.

If you're not registered, please consider doing so. It's easy - just click the "Register" link at the top

right corner of the page. Our forum needs members like you to contribute to the site in order to survive.

We are a community of boat lovers and Hydrostream enthusiasts here; we are happy to help anyone

who may need advice or guidance for their 'Stream; and we encourage members to offer their advice

and guidance to others as well. Thank you for visiting our forums, and please register.

We're better than Facebook.

Registering only takes a few minutes and you can do so by CLICKING HERE

If you are a member, don't forget to log in to take full advantage of the forum.

79 Vulture Recore

-

Hippie459MN

- Site Admin

- Posts: 4002

- Joined: Mar 25, 2009 7:31 pm

- Location: Nowthen, MN

- Has thanked: 364 times

- Been thanked: 86 times

- Contact:

Re: Another Hydrostream fanatic on board.

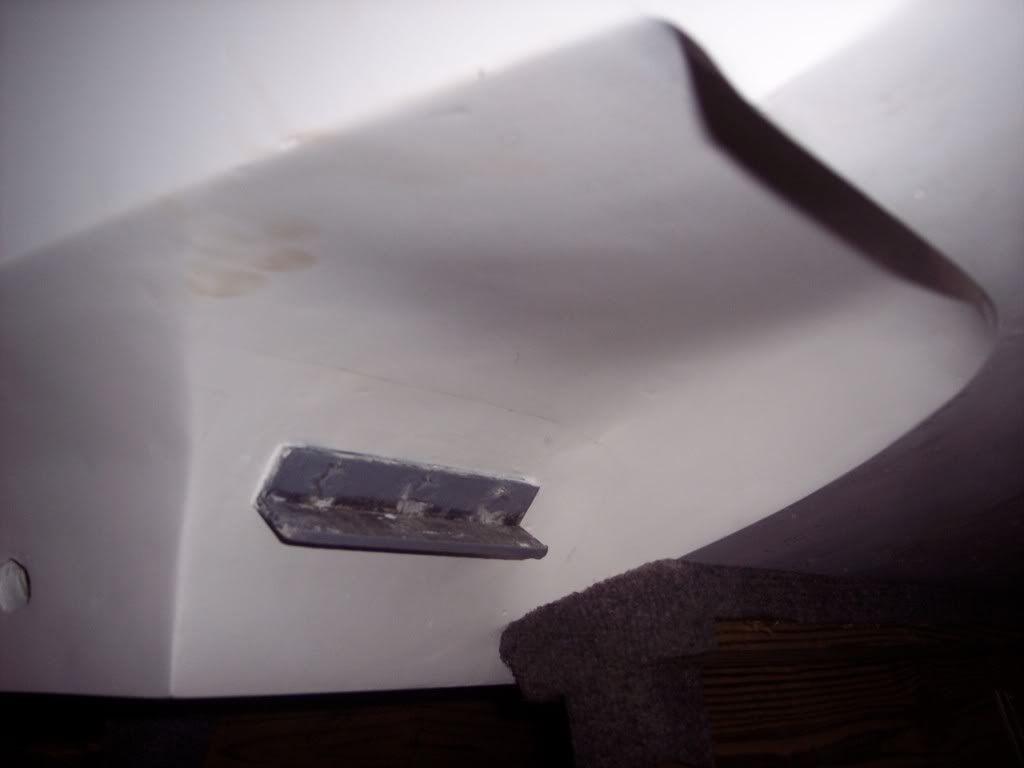

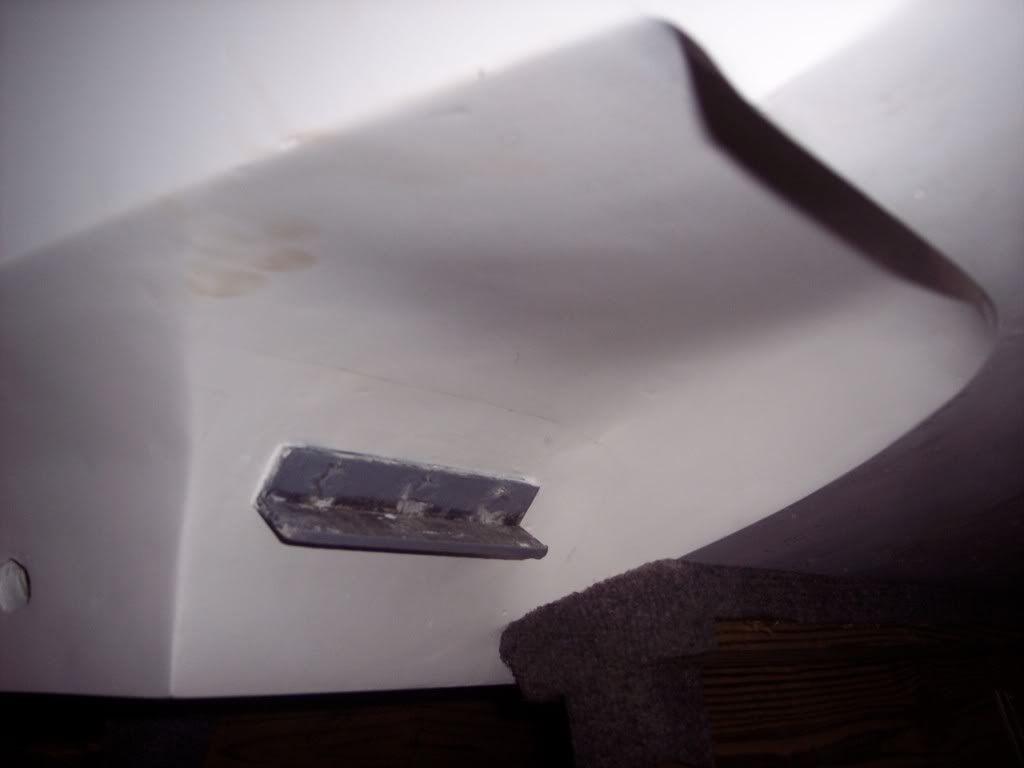

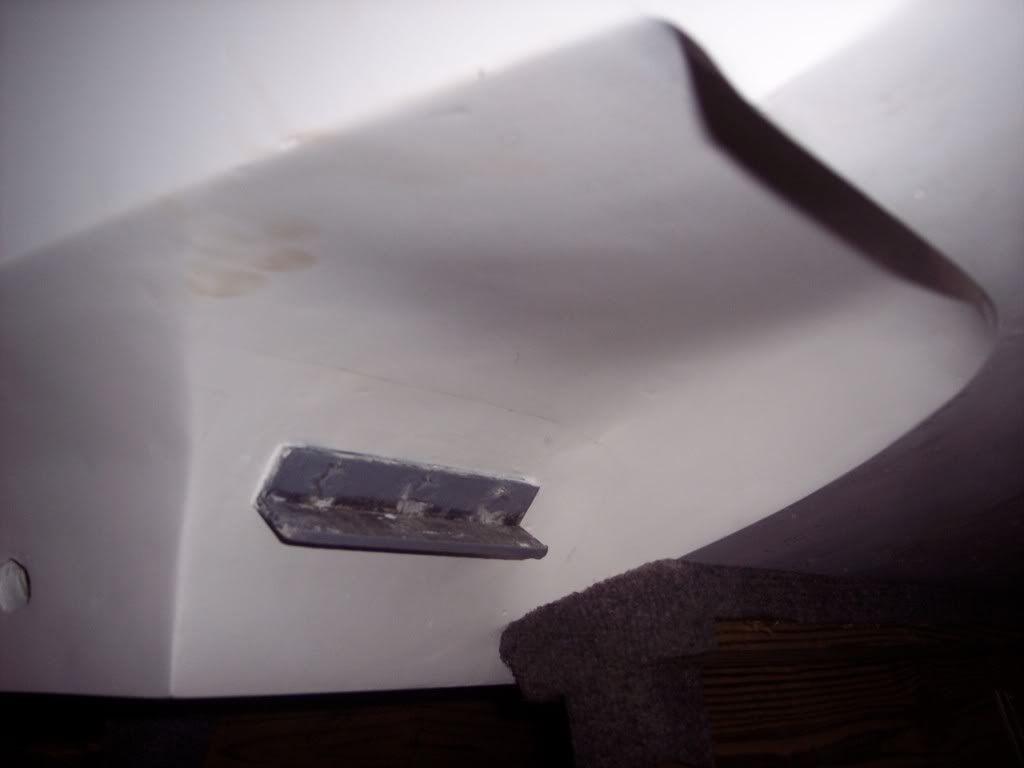

Its not my boat but here is the picture from a Vulture with the little aluminum strips. I can make them easy enough out of some angle. I just need to know the proper placement and best way to mount them so it wont cause any future woater/rot issues.

-Kevin

Project Vulture | Project Vector | Project Vamp | Project Vixen

The Vulture Wish List | Project CobraJet

1977 HydroStream Vulture - Worlds longest ongoing project.

1982 Hydrostream Vector

1982 Hydrostream Vamp

1973 Hydrostream Vixen

1976 CobraJet Jet Boat - Outboard conversion project

1976 Pontoon - aka The Family Truckster

Project Vulture | Project Vector | Project Vamp | Project Vixen

The Vulture Wish List | Project CobraJet

1977 HydroStream Vulture - Worlds longest ongoing project.

1982 Hydrostream Vector

1982 Hydrostream Vamp

1973 Hydrostream Vixen

1976 CobraJet Jet Boat - Outboard conversion project

1976 Pontoon - aka The Family Truckster

-

VultureNo2

- Hydrostream know it all

- Posts: 997

- Joined: Nov 20, 2009 11:35 pm

- Location: Pleasant Prairie, WI

- Been thanked: 2 times

Re: Another Hydrostream fanatic on board.

I have them on this one. You will definately want something similar. I will post a picture of the ones on my 79. Bill

-

VultureNo2

- Hydrostream know it all

- Posts: 997

- Joined: Nov 20, 2009 11:35 pm

- Location: Pleasant Prairie, WI

- Been thanked: 2 times

Re: Another Hydrostream fanatic on board.

Those look differant then mine I think but the same idea. I will look closer tonight. Bill

Re: Another Hydrostream fanatic on board.

Looks like they serve no purpose other than disturb the water/air pocket

no preasure , no strength needed

either bond them on with 5200 (no screws) or grind and incorporate/glass something right to the hull

that way it will look factory built

no preasure , no strength needed

either bond them on with 5200 (no screws) or grind and incorporate/glass something right to the hull

that way it will look factory built

<> God is Great , Beer is Good , Boaters are Crazy <>

-

VultureNo2

- Hydrostream know it all

- Posts: 997

- Joined: Nov 20, 2009 11:35 pm

- Location: Pleasant Prairie, WI

- Been thanked: 2 times

Re: Another Hydrostream fanatic on board.

Hippie, I looked at mine and they are exactly the same as the one you show. They are on the 79 but were not on my 77. Bill

-

VultureNo2

- Hydrostream know it all

- Posts: 997

- Joined: Nov 20, 2009 11:35 pm

- Location: Pleasant Prairie, WI

- Been thanked: 2 times

Re: Another Hydrostream fanatic on board.

Chet, I was planning on sanding after I get the core out. You mention grinding. What did you use to grind. Do I grind because I want a rough finish on the remaining glass to bond to, or is it ok to sand it all off? Please advise. Bill

-

ccrick

- Hydrostream know it all

- Posts: 679

- Joined: Apr 07, 2009 8:07 pm

- Location: Sterling Heights Mi.

Re: Another Hydrostream fanatic on board.

I don't know what Chet used But I used 36 grit on a grinder left a good surface for the new stuff to adhere. This is going to be the worst part of the job. By the way Bill, hows the transom? Git us sum pic's man!

1980 Viking

150 Black Max

150 Black Max

Re: Another Hydrostream fanatic on board.

When I did the core I used a 4 1/2" 36 gritt flapper disk on a grinder but this works a little better.

I took the backing plate off so the sanding disk is plyable. It leaves the glass a little smoother where the smaller grinder left some groves.

I took the backing plate off so the sanding disk is plyable. It leaves the glass a little smoother where the smaller grinder left some groves.

Samari on s&f

Chet Olson

75 viper 2.4 200, 130 shot of NOS

91 vegas loaned out

79 vking project 2.5 280

Chet Olson

75 viper 2.4 200, 130 shot of NOS

91 vegas loaned out

79 vking project 2.5 280

-

VultureNo2

- Hydrostream know it all

- Posts: 997

- Joined: Nov 20, 2009 11:35 pm

- Location: Pleasant Prairie, WI

- Been thanked: 2 times

Re: Another Hydrostream fanatic on board.

Thanks guys. I am still removing core. It's pretty solid on the starboard side and coming out in little airline wine bottle corks. It's taking longer then I thought but going slow and being careful of the bottom. I still have the jackplate bolts pretty rusted in place to deal with before I can get a good look at the transom. As soon as I get the core on the sides done and the footwell, that's next. Kinda hoping it's not rotten, but if it is, it'll come out too. I still have work to do in the footwell. I am calling it that because I don't know what else to call it. Looks like someone put plywood over the existing floor and glassed that in. there was nn drain hole from there to the back of the boat. Got a bad feeling about rot under there. Still waiting on a answer on a place to work.  I am hoping to get a place. If it doesn't happen soon I will have to consider doing it in the garage. I still have work that can be done before I am forced to make a decision. Still as determined as ever. Bill

I am hoping to get a place. If it doesn't happen soon I will have to consider doing it in the garage. I still have work that can be done before I am forced to make a decision. Still as determined as ever. Bill

-

Hippie459MN

- Site Admin

- Posts: 4002

- Joined: Mar 25, 2009 7:31 pm

- Location: Nowthen, MN

- Has thanked: 364 times

- Been thanked: 86 times

- Contact:

Re: Another Hydrostream fanatic on board.

I wish I had at least a garage cause if I did I would have alot more done to mine.

Lats 2 places I was going to work on mine at fell through so its no go for me right now. I was planning on having all the core and transom out by the end of the year but not gonna happen unless I can find some work space before then.

Good luck and keep them pictures coming.

Lats 2 places I was going to work on mine at fell through so its no go for me right now. I was planning on having all the core and transom out by the end of the year but not gonna happen unless I can find some work space before then.

Good luck and keep them pictures coming.

-Kevin

Project Vulture | Project Vector | Project Vamp | Project Vixen

The Vulture Wish List | Project CobraJet

1977 HydroStream Vulture - Worlds longest ongoing project.

1982 Hydrostream Vector

1982 Hydrostream Vamp

1973 Hydrostream Vixen

1976 CobraJet Jet Boat - Outboard conversion project

1976 Pontoon - aka The Family Truckster

Project Vulture | Project Vector | Project Vamp | Project Vixen

The Vulture Wish List | Project CobraJet

1977 HydroStream Vulture - Worlds longest ongoing project.

1982 Hydrostream Vector

1982 Hydrostream Vamp

1973 Hydrostream Vixen

1976 CobraJet Jet Boat - Outboard conversion project

1976 Pontoon - aka The Family Truckster

-

- Random Topics

- Replies

- Views

- Last post

-

- 8Replies

- 10547 Views

- Last post by Hippie459MN

Jul 04, 2012 10:39 am

-

- 9Replies

- 26498 Views

- Last post by YDOC462

Jul 16, 2012 1:30 pm

-

- 7Replies

- 11079 Views

- Last post by idvette

Jul 06, 2012 6:45 am

-

- 11Replies

- 29509 Views

- Last post by Hippie459MN

Aug 02, 2012 3:53 pm

-

- 9Replies

- 22138 Views

- Last post by RussF

Sep 21, 2012 7:42 pm