Welcome to HydrostreamForums.com

If you're not registered, please consider doing so. It's easy - just click the "Register" link at the top

right corner of the page. Our forum needs members like you to contribute to the site in order to survive.

We are a community of boat lovers and Hydrostream enthusiasts here; we are happy to help anyone

who may need advice or guidance for their 'Stream; and we encourage members to offer their advice

and guidance to others as well. Thank you for visiting our forums, and please register.

We're better than Facebook.

Registering only takes a few minutes and you can do so by CLICKING HERE

If you are a member, don't forget to log in to take full advantage of the forum.

If you're not registered, please consider doing so. It's easy - just click the "Register" link at the top

right corner of the page. Our forum needs members like you to contribute to the site in order to survive.

We are a community of boat lovers and Hydrostream enthusiasts here; we are happy to help anyone

who may need advice or guidance for their 'Stream; and we encourage members to offer their advice

and guidance to others as well. Thank you for visiting our forums, and please register.

We're better than Facebook.

Registering only takes a few minutes and you can do so by CLICKING HERE

If you are a member, don't forget to log in to take full advantage of the forum.

1980 Viper Rebirth

-

AdamDK

- Moderator

- Posts: 327

- Joined: Jul 19, 2016 6:58 pm

- Location: Oshawa, Ontario (near Toronto)

- Has thanked: 45 times

- Been thanked: 73 times

Re: 1980 Viper Rebirth

I think Drew is holding back on the Venom. July 1st weekend there was a run up and down the lake....on their way down he was in last place being beaten by a Seadoo.

I have video proof on my phone. Ask Hippie, I showed him.

I have video proof on my phone. Ask Hippie, I showed him.

-

idvette

- Hydrostream know it all

- Posts: 527

- Joined: Aug 08, 2011 10:22 pm

- Location: Peterborough Ontario

- Has thanked: 11 times

- Been thanked: 34 times

Re: 1980 Viper Rebirth

I have videos shot from that boat with the previous owner driving. It's been over 100mph, and feels effortless doing it. Drew may need more seat time to get comfortable in it, but the potential is there!

[ Post made via Android ]

[ Post made via Android ]

1988 Canadian Edition Vision Sold

1990 Hydrostream Virage Stage 3 Turbo

1990 Hydrostream Virage Stage 3 Turbo

-

AdamDK

- Moderator

- Posts: 327

- Joined: Jul 19, 2016 6:58 pm

- Location: Oshawa, Ontario (near Toronto)

- Has thanked: 45 times

- Been thanked: 73 times

Re: 1980 Viper Rebirth

Friday Sept 20th, 2019:

Apologies for the delay. Busy weekends happened.

After I had finished grinding the deck, I laid down overlapping strips of 1.5oz CSM over the entire deck's underside. except for the dash. I left that bare for when I clamped in the new plywood.

Next, using my old dash as a rough template, I cut a new one out of 3/4" marine plywood, and trimmed it down accordingly to fit.

I "primed" the dash with resin and doubled the catalyst (4%), and let that sit. In the meantime, I whipped up a batch of CoreBond, and put in "wedges" in the notches where the windshield frame screws in to.

Back to the dash, I laid on 2 layers of 1.5oz CSM, and clamped her into place.

Was busy all Saturday, so this is what I got done today:

Sunday Sept 22nd, 2019:

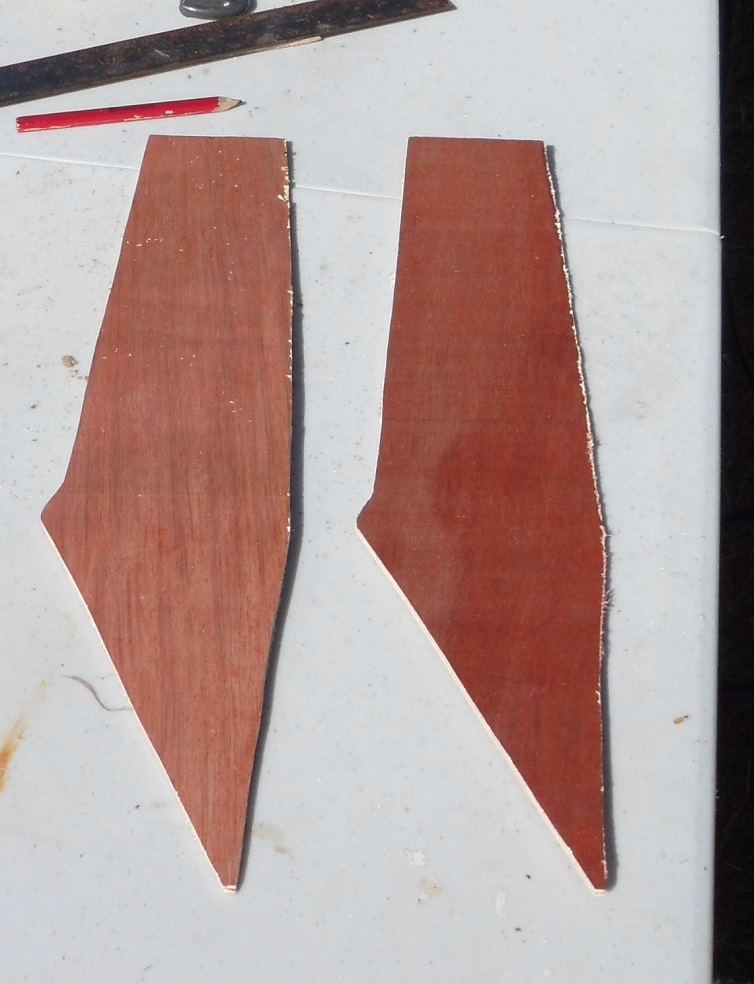

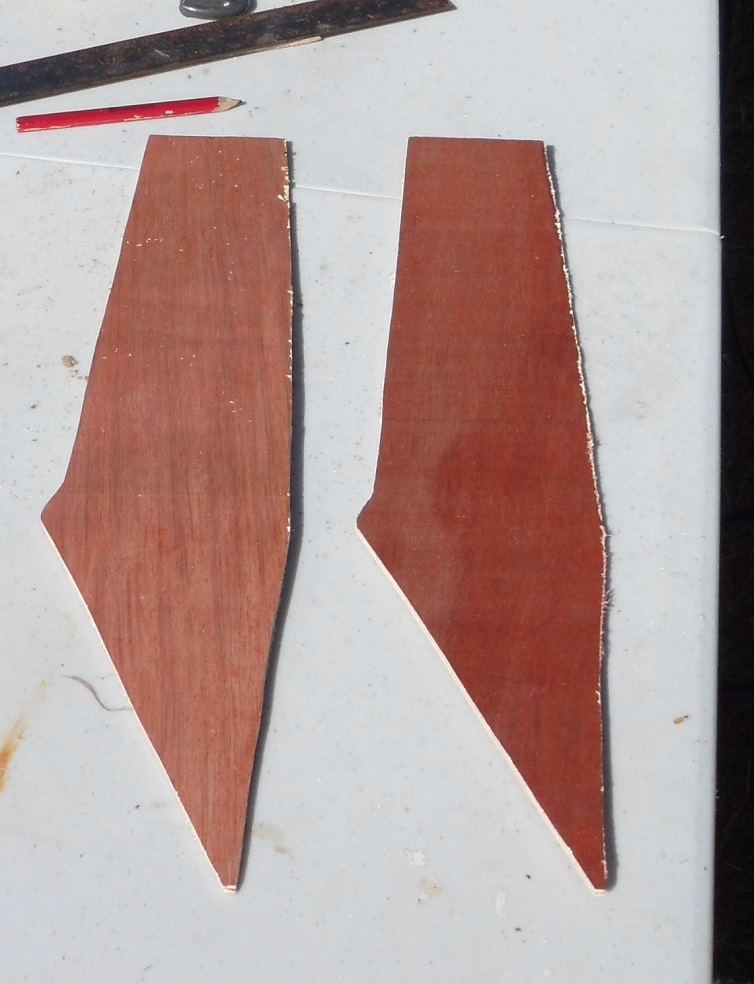

I cut out strips of 1/4" exterior mahogany plywood for the sides. I'll be laying on 2 layers of them for a 1/2" combined thickness. This will be replacing the 1/4" (or 3/8") strip of original plywood.

Here they are at their full 8 foot length, but i decided to trim off the forward foot as I plan on adding extended gussets on both sides of the dash.

Soaked them in resin, and clamped into place.

Starboard side...

I didn't take pictures for this really, but I cut a strip of 3/4" marine ply for the splashwell "cross-brace" (as I call it...), and clamped that in.

Added in 2 wedges, CoreBonded and resined into place.

Port side:

After a few hours, I removed most of the clamps, mixed up some more resin, and re-clamped the sections to get the proper "bend" near the splashwell.

Also slathered resin on the outer side of the plywood panels. I plan on glassing these over tomorrow, so I'll still be able to maintain a chemical bond.

Apologies for the delay. Busy weekends happened.

After I had finished grinding the deck, I laid down overlapping strips of 1.5oz CSM over the entire deck's underside. except for the dash. I left that bare for when I clamped in the new plywood.

Next, using my old dash as a rough template, I cut a new one out of 3/4" marine plywood, and trimmed it down accordingly to fit.

I "primed" the dash with resin and doubled the catalyst (4%), and let that sit. In the meantime, I whipped up a batch of CoreBond, and put in "wedges" in the notches where the windshield frame screws in to.

Back to the dash, I laid on 2 layers of 1.5oz CSM, and clamped her into place.

Was busy all Saturday, so this is what I got done today:

Sunday Sept 22nd, 2019:

I cut out strips of 1/4" exterior mahogany plywood for the sides. I'll be laying on 2 layers of them for a 1/2" combined thickness. This will be replacing the 1/4" (or 3/8") strip of original plywood.

Here they are at their full 8 foot length, but i decided to trim off the forward foot as I plan on adding extended gussets on both sides of the dash.

Soaked them in resin, and clamped into place.

Starboard side...

I didn't take pictures for this really, but I cut a strip of 3/4" marine ply for the splashwell "cross-brace" (as I call it...), and clamped that in.

Added in 2 wedges, CoreBonded and resined into place.

Port side:

After a few hours, I removed most of the clamps, mixed up some more resin, and re-clamped the sections to get the proper "bend" near the splashwell.

Also slathered resin on the outer side of the plywood panels. I plan on glassing these over tomorrow, so I'll still be able to maintain a chemical bond.

-

alaskastreamin

- Hydrostream know it all

- Posts: 513

- Joined: Feb 10, 2012 8:01 pm

- Location: Sitka Alaska / Okanogan,WA

- Has thanked: 5 times

- Been thanked: 158 times

- Contact:

Re: 1980 Viper Rebirth

Looking good buddy!!

[ Post made via iPhone ]

[ Post made via iPhone ]

Ron Pratt

Okanogan, WA

Viper/ 2.5L 200 Merc (SOLD)

1991 "the last" Virage/ 15" 280

2003 9’ Mini Virage/ 15 hp Honda 4-stroke

1989 Voyager/ 300 Promax

1989 HST / 2.5L 200 Merc

http://www.prattcustoms.com

Okanogan, WA

Viper/ 2.5L 200 Merc (SOLD)

1991 "the last" Virage/ 15" 280

2003 9’ Mini Virage/ 15 hp Honda 4-stroke

1989 Voyager/ 300 Promax

1989 HST / 2.5L 200 Merc

http://www.prattcustoms.com

-

tnelson77

- Regular

- Posts: 106

- Joined: Aug 01, 2018 11:05 am

- Location: Minneapolis Minnesota

- Has thanked: 151 times

- Been thanked: 50 times

Re: 1980 Viper Rebirth

Looks great! Keep up the good work!

'78 Viking/ '98 Mercury 225 ProMax

500+ pictures of build: https://www.flickr.com/photos/152974368@N02/albums/72157708863869223

Videos of build: https://www.youtube.com/channel/UCWRAfGZVq4a3R-W7JdJeFeQ/videos?view_as=subscriber

500+ pictures of build: https://www.flickr.com/photos/152974368@N02/albums/72157708863869223

Videos of build: https://www.youtube.com/channel/UCWRAfGZVq4a3R-W7JdJeFeQ/videos?view_as=subscriber

-

AdamDK

- Moderator

- Posts: 327

- Joined: Jul 19, 2016 6:58 pm

- Location: Oshawa, Ontario (near Toronto)

- Has thanked: 45 times

- Been thanked: 73 times

Re: 1980 Viper Rebirth

Saturday Sept 28th, 2019:

Unfortunately, last week kicked my butt with work. Not getting home until 630-7pm every day didn't leave any time to work on the boat.

With the weather turning, I didn't want to leave the deck protected by just a crappy tarp.

Time to rebuild my hoisting frame and get her inside the shelter.

Hopefully I can knock off a few things this coming week. First, cleaning up all the crap and re-organizing my tools. Second, getting the side and centre braces installed on the dash and glassed in.

Once that's done, I can move the deck back outside onto its sawhorses and flip it right-side-up and leave it until I get the hull structure finished.

My 5-year wedding anniversary was Friday, and I worked, and wife worked today, but we're both off Sunday, so she wants a "date" day. Which means boat gets neglected.

Unfortunately, last week kicked my butt with work. Not getting home until 630-7pm every day didn't leave any time to work on the boat.

With the weather turning, I didn't want to leave the deck protected by just a crappy tarp.

Time to rebuild my hoisting frame and get her inside the shelter.

Hopefully I can knock off a few things this coming week. First, cleaning up all the crap and re-organizing my tools. Second, getting the side and centre braces installed on the dash and glassed in.

Once that's done, I can move the deck back outside onto its sawhorses and flip it right-side-up and leave it until I get the hull structure finished.

My 5-year wedding anniversary was Friday, and I worked, and wife worked today, but we're both off Sunday, so she wants a "date" day. Which means boat gets neglected.

-

proprider

- Regular

- Posts: 187

- Joined: Aug 15, 2012 9:18 pm

- Location: Deerfield, Mi

- Been thanked: 12 times

Re: 1980 Viper Rebirth

Amazing work Adam! Awesome documentation of the process.

[ Post made via iPhone ]

[ Post made via iPhone ]

-

AdamDK

- Moderator

- Posts: 327

- Joined: Jul 19, 2016 6:58 pm

- Location: Oshawa, Ontario (near Toronto)

- Has thanked: 45 times

- Been thanked: 73 times

Re: 1980 Viper Rebirth

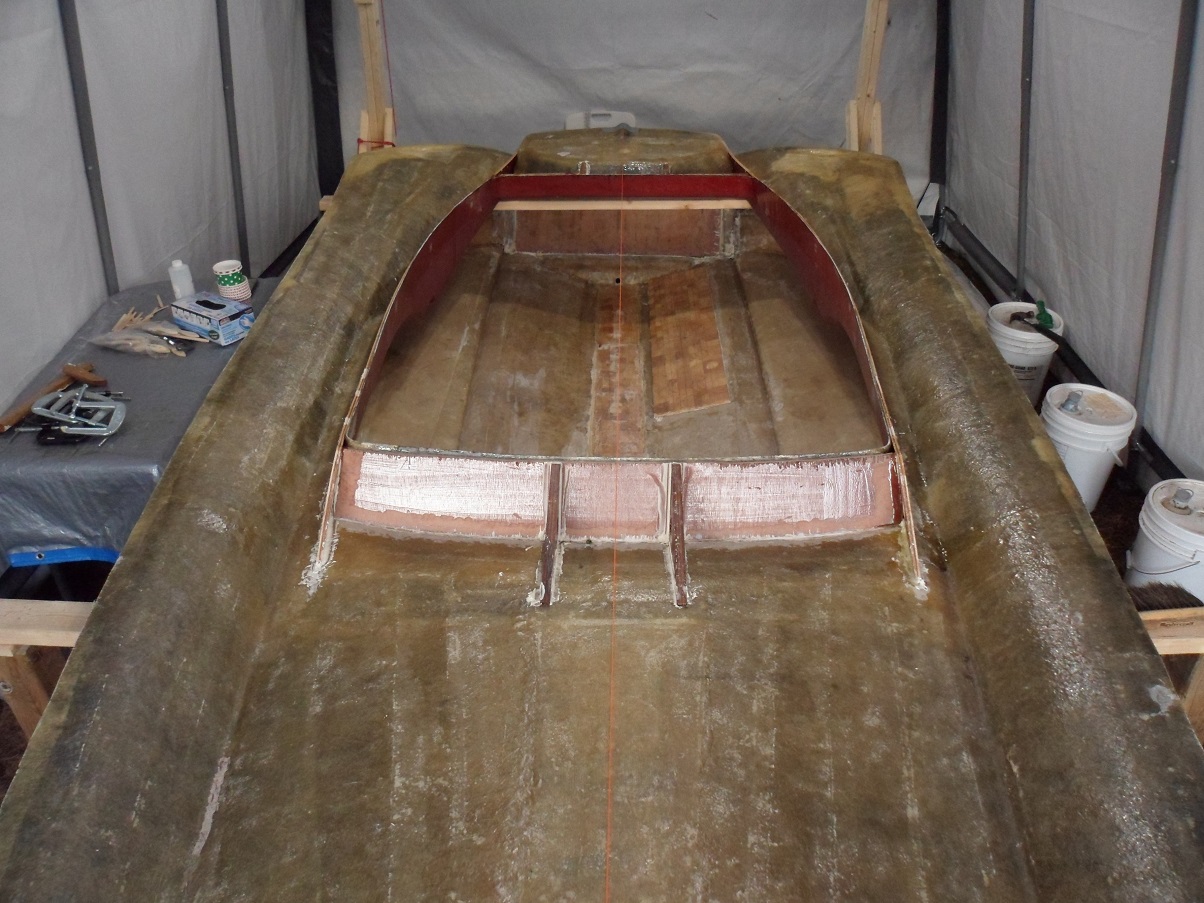

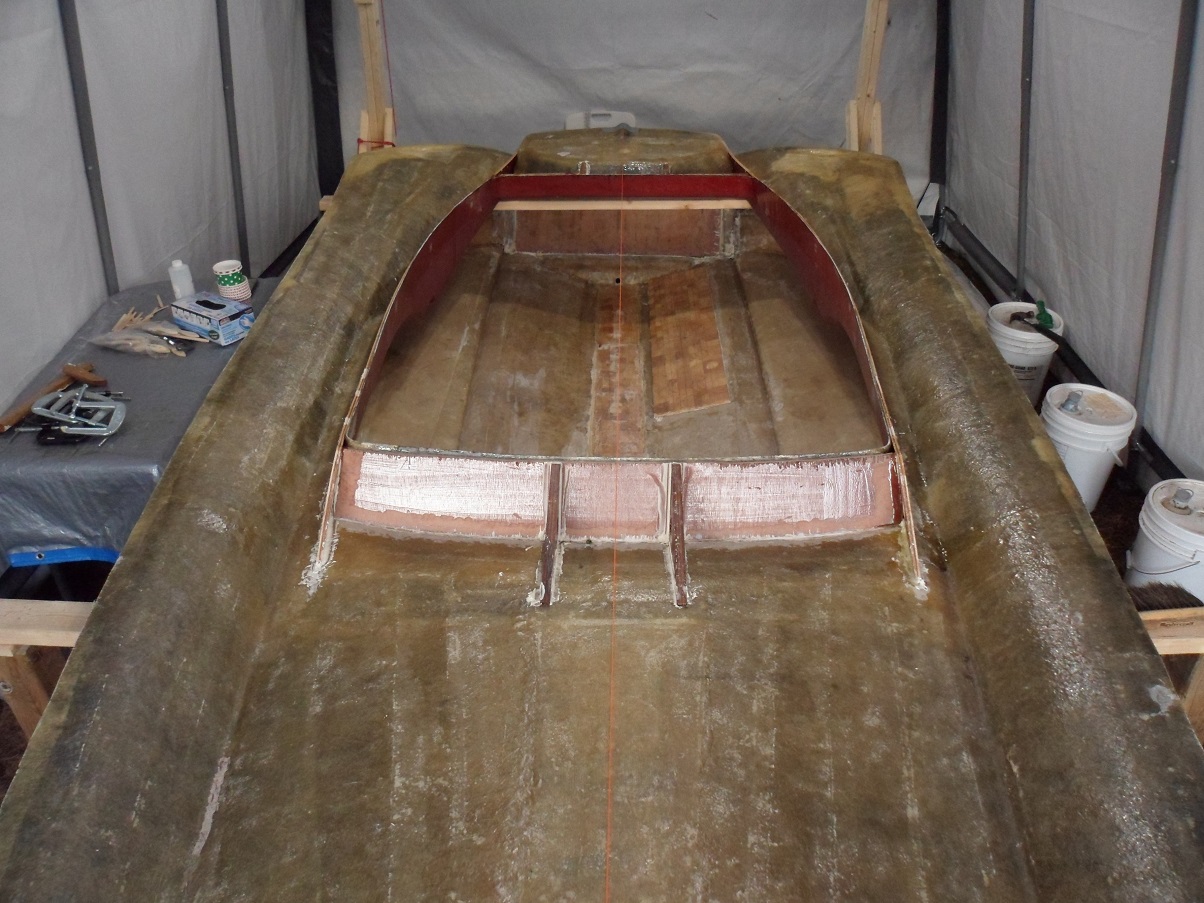

Wednesday Oct 2nd, 2019:

I added 2 more pieces of 3/4" marine plywood to the splashwell bulkhead. Simply forward thinking about how I'll have the rear bench seat secured in place. I'm leaning towards a set of draw latches at the top back of the seat, this way I can mount hinges at the front bottom of the bench, and the whole bench will fold forward allowing access under the splashwell.

(The orange string is just for marking the centre-line of the deck.)

Next I worked on a set of gussets for the dash. I used styrofoam to create a template, then cut 3/4" plywood pieces to match.

I primed the gussets with resin, letting them sit for about 45 minutes.

Then mixed up some CoreBond, catalyzed, and put it in a Ziploc bag. (thanks Ron! @alaskastreamin )

Squeezed it out like icing, set the gussets in place, and then weighted down.

They are 9 inches apart, which leaves plenty of room for a hydraulic steering helm (a SeaStar Pro helm is 4.5" diameter.)

Weather up here is starting to cool off....I'm trying to get as much done as I can before temperatures start dropping below 65 on a regular basis.

I added 2 more pieces of 3/4" marine plywood to the splashwell bulkhead. Simply forward thinking about how I'll have the rear bench seat secured in place. I'm leaning towards a set of draw latches at the top back of the seat, this way I can mount hinges at the front bottom of the bench, and the whole bench will fold forward allowing access under the splashwell.

(The orange string is just for marking the centre-line of the deck.)

Next I worked on a set of gussets for the dash. I used styrofoam to create a template, then cut 3/4" plywood pieces to match.

I primed the gussets with resin, letting them sit for about 45 minutes.

Then mixed up some CoreBond, catalyzed, and put it in a Ziploc bag. (thanks Ron! @alaskastreamin )

Squeezed it out like icing, set the gussets in place, and then weighted down.

They are 9 inches apart, which leaves plenty of room for a hydraulic steering helm (a SeaStar Pro helm is 4.5" diameter.)

Weather up here is starting to cool off....I'm trying to get as much done as I can before temperatures start dropping below 65 on a regular basis.

-

AdamDK

- Moderator

- Posts: 327

- Joined: Jul 19, 2016 6:58 pm

- Location: Oshawa, Ontario (near Toronto)

- Has thanked: 45 times

- Been thanked: 73 times

Re: 1980 Viper Rebirth

Tuesday October 8th, 2019:

Had the day off today. Sunny and almost 70 degrees. Time to work on the dash edge gussets.

For the starboard side, I templated out a piece of 1/4" exterior mahogany plywood, then cut a second piece to match.

Laid the inner piece down, brushed on some resin, put on a layer of CSM, then the outer piece. Weighted down with some interlocking bricks and a 40 pound cinder block.

Let it cure up for about an hour and half, then templated out pieces for the port side.

I sandwiched those 2 pieces, then went to work setting the starboard gusset in place.

CoreBonded the deck-side edge, then clamped into place.

After another hour and half, removed the starboard clamps, then set the port gusset into place.

This is all for today.

Next is to sand all the excess CoreBond off, then start glassing over it all.

Had the day off today. Sunny and almost 70 degrees. Time to work on the dash edge gussets.

For the starboard side, I templated out a piece of 1/4" exterior mahogany plywood, then cut a second piece to match.

Laid the inner piece down, brushed on some resin, put on a layer of CSM, then the outer piece. Weighted down with some interlocking bricks and a 40 pound cinder block.

Let it cure up for about an hour and half, then templated out pieces for the port side.

I sandwiched those 2 pieces, then went to work setting the starboard gusset in place.

CoreBonded the deck-side edge, then clamped into place.

After another hour and half, removed the starboard clamps, then set the port gusset into place.

This is all for today.

Next is to sand all the excess CoreBond off, then start glassing over it all.

-

- Random Topics

- Replies

- Views

- Last post

-

- 1Replies

- 4219 Views

- Last post by Hydrostream Bot

Aug 18, 2010 5:12 pm

-

- 1Replies

- 4035 Views

- Last post by Hydrostream Bot

Aug 18, 2010 10:09 pm

-

- 1Replies

- 5528 Views

- Last post by Hydrostream Bot

Aug 19, 2010 11:09 am

-

- 9Replies

- 14961 Views

- Last post by RedDemon

Aug 22, 2010 2:11 am

-

- 1Replies

- 5427 Views

- Last post by Hydrostream Bot

Aug 19, 2010 7:56 pm