Friday Sept 20th, 2019:

Apologies for the delay. Busy weekends happened.

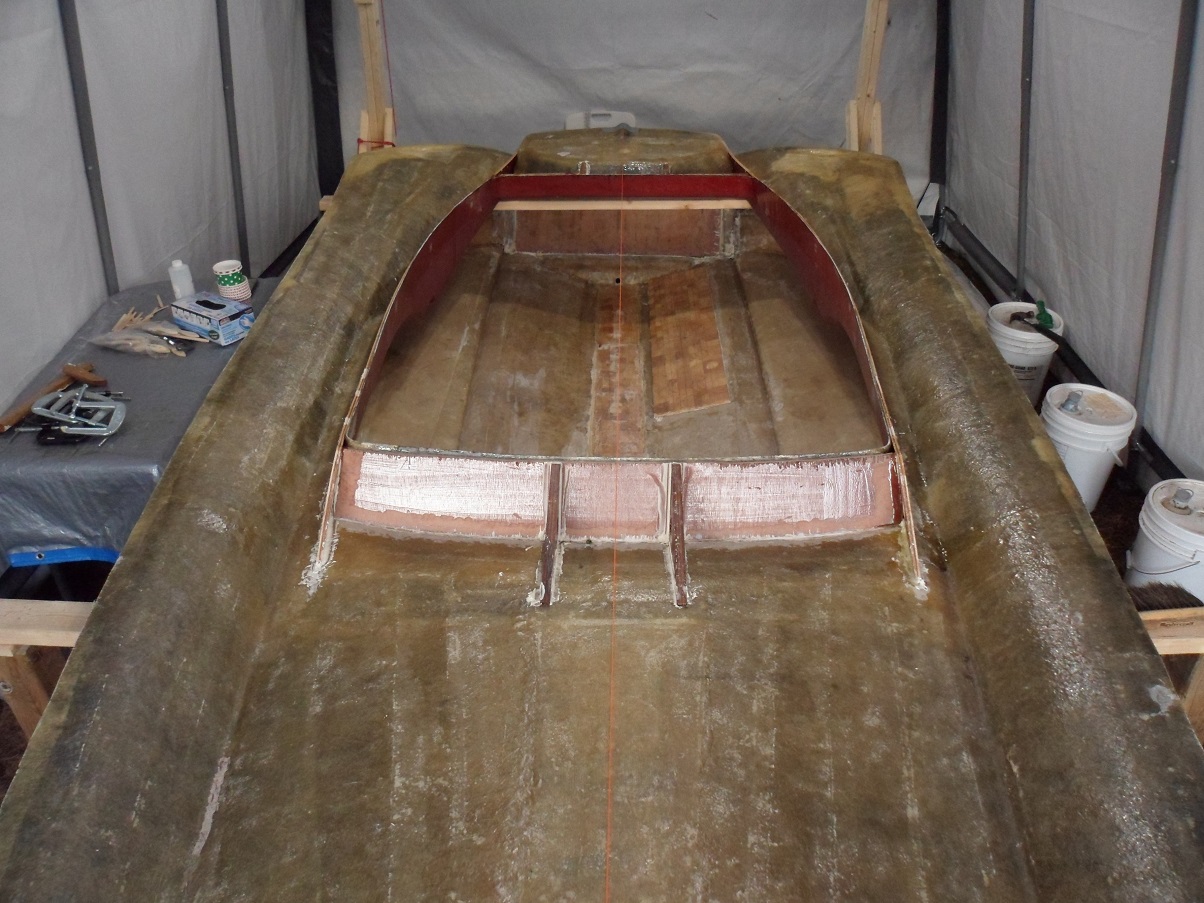

After I had finished grinding the deck, I laid down overlapping strips of 1.5oz CSM over the entire deck's underside. except for the dash. I left that bare for when I clamped in the new plywood.

Next, using my old dash as a rough template, I cut a new one out of 3/4" marine plywood, and trimmed it down accordingly to fit.

I "primed" the dash with resin and doubled the catalyst (4%), and let that sit. In the meantime, I whipped up a batch of CoreBond, and put in "wedges" in the notches where the windshield frame screws in to.

Back to the dash, I laid on 2 layers of 1.5oz CSM, and clamped her into place.

Was busy all Saturday, so this is what I got done today:

Sunday Sept 22nd, 2019:

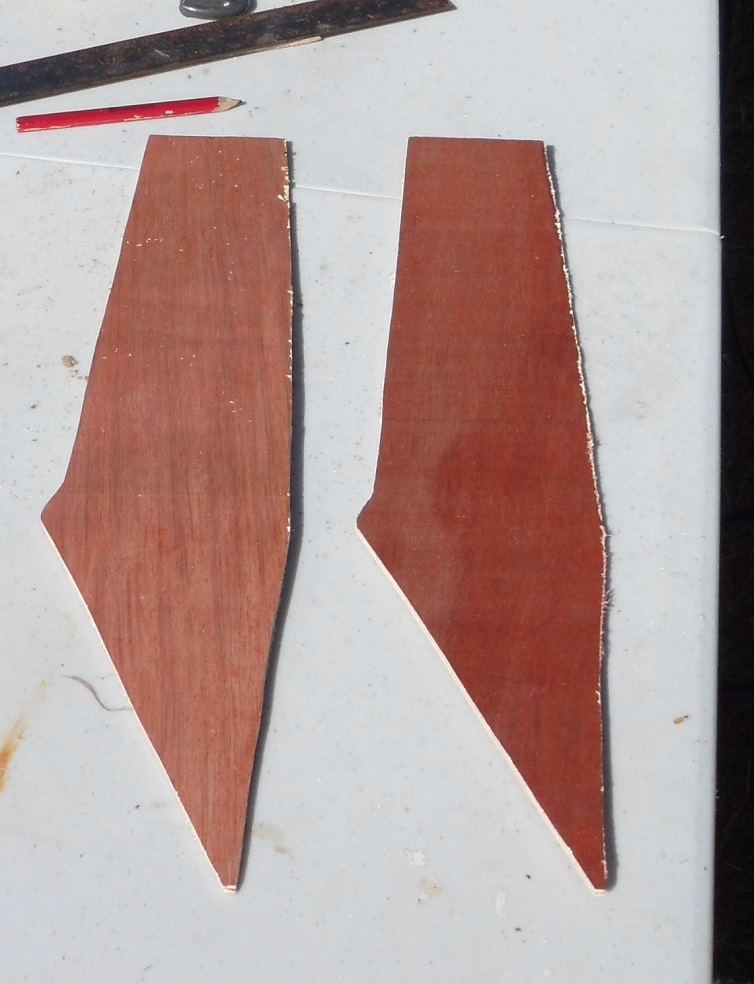

I cut out strips of 1/4" exterior mahogany plywood for the sides. I'll be laying on 2 layers of them for a 1/2" combined thickness. This will be replacing the 1/4" (or 3/8") strip of original plywood.

Here they are at their full 8 foot length, but i decided to trim off the forward foot as I plan on adding extended gussets on both sides of the dash.

Soaked them in resin, and clamped into place.

Starboard side...

I didn't take pictures for this really, but I cut a strip of 3/4" marine ply for the splashwell "cross-brace" (as I call it...), and clamped that in.

Added in 2 wedges, CoreBonded and resined into place.

Port side:

After a few hours, I removed most of the clamps, mixed up some more resin, and re-clamped the sections to get the proper "bend" near the splashwell.

Also slathered resin on the outer side of the plywood panels. I plan on glassing these over tomorrow, so I'll still be able to maintain a chemical bond.